Crucial Role in Battery Performance

In the fast-paced development of battery-powered technologies, battery liquid cold plates have become a key component in ensuring the stability and efficiency of battery systems they help maintain consistent operating temperatures which is essential for safety longevity and performance

How Liquid Cold Plates Work

Battery liquid cold plates use a liquid cooling mechanism where a flat metal plate with internal channels allows coolant—typically a water and antifreeze mixture—to circulate through the system as the battery generates heat the cold plate absorbs it and the coolant carries the heat away to the environment this process regulates cell temperature and prevents issues such as thermal runaway or accelerated degradation

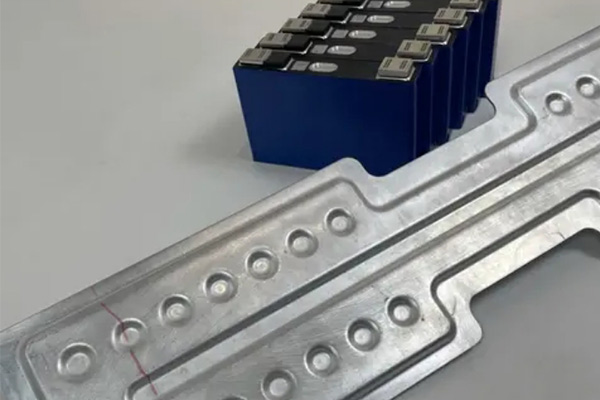

Precision Engineering and Materials

These cold plates are made using high thermal conductivity materials like aluminum or copper to maximize heat transfer efficiency their internal channel designs are carefully optimized to distribute coolant evenly across all necessary battery regions many modern designs also include integrated sensors and smart control systems that enable real time thermal management adjustments based on actual battery conditions

Advantages Over Air Cooling

Compared to air cooling systems battery liquid cold plates deliver far superior performance in high power and high energy density applications they help maintain ideal operating temperatures which increases energy output extends cycle life and enhances system reliability

Widespread Applications and Future Prospects

Battery liquid cold plates are commonly used in electric vehicles stationary energy storage systems and high performance portable electronics as demand for powerful and reliable batteries continues to rise the need for advanced cooling technologies like these plates will become increasingly vital propelling innovation in thermal management solutions