Liquid cooling plates have become essential across numerous industries, thanks to their superior heat dissipation capabilities. They address the increasingly demanding thermal management requirements of modern technologies, ensuring both performance and reliability.

Electronics Industry: Enabling High-Performance Computing

In the electronics sector, liquid cooling plates are transforming thermal management—especially in high-performance computing. Data centers, filled with thousands of servers running CPUs, GPUs, and other critical components, generate vast amounts of heat. By being mounted directly on these heat-intensive components, liquid cooling plates efficiently draw heat away, preventing overheating-related slowdowns or system failures. This allows servers to maintain peak performance, essential for applications like cloud computing, big data analytics, and online gaming.

Enthusiasts and professionals using high-performance personal computers also rely on liquid cooling plates—especially when overclocking processors or utilizing high-end graphics cards. During tasks like 3D rendering or immersive gaming, these components can produce intense heat. Integrated with liquid cooling loops, the plates help maintain safe operating temperatures, enhancing both system performance and component longevity.

Automotive Industry: Supporting the EV Revolution

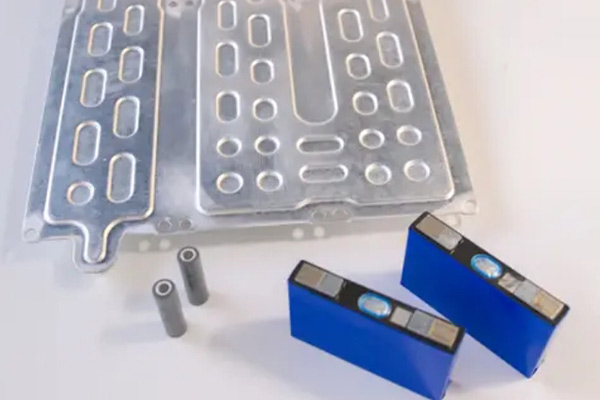

In the automotive world—particularly the rapidly growing electric vehicle (EV) market—liquid cooling plates play a critical role. EV battery packs generate significant heat during both charging and discharging. To ensure optimal performance, safety, and extended battery life, liquid cooling plates are embedded within the battery design, often wrapping around cells or modules. This is particularly crucial during fast-charging, where high current leads to rapid heat buildup. Liquid cooling plates mitigate this by maintaining a stable temperature, thereby improving charging efficiency and preventing thermal runaway—an uncontrolled and potentially dangerous overheating scenario.

Beyond batteries, EV drivetrain components like electric motors and power electronics also benefit from liquid cooling. These systems operate under high loads, and effective cooling helps sustain efficiency, reliability, and overall vehicle range.

Renewable Energy Systems: Enhancing System Efficiency

Liquid cooling plates are also integral to renewable energy technologies. In solar power systems, power conversion units like inverters convert direct current (DC) from solar panels into alternating current (AC) for grid use. These inverters generate substantial heat, and liquid cooling plates help manage it effectively, ensuring continuous and efficient operation. Stable inverter performance translates into more reliable energy output and improved system efficiency.

In wind turbines, control units and power electronics are exposed to harsh environmental conditions while generating heat during operation. Liquid cooling plates protect these sensitive components by maintaining safe operating temperatures, thus ensuring reliable turbine performance even in extreme climates.

Industrial Applications: Boosting Equipment Reliability

Industrial environments host a wide array of high-power equipment where precise thermal control is vital. High-power lasers used in applications such as cutting, welding, and engraving produce significant heat. Liquid cooling plates are used to cool laser diodes and essential optics, maintaining precision and consistent output—critical for quality-driven manufacturing.

Similarly, industrial power inverters, responsible for converting DC to AC in large-scale power systems, depend on liquid cooling to manage heat from high-power handling. Furthermore, in high-speed machining or heavy-duty manufacturing operations, liquid cooling plates are used in motors, spindles, and bearings to reduce friction, wear, and heat-induced degradation—ultimately improving productivity and equipment lifespan.

Conclusion: A Growing Role in Advanced Thermal Management

From electronics and automotive to renewable energy and industrial machinery, liquid cooling plates have established themselves as a foundational solution for advanced thermal management. As technologies become more powerful and compact, and the demand for efficient heat dissipation rises, the role of liquid cooling plates will continue to expand—driving innovation, performance, and safety across diverse sectors.