The Bonnell spring machine stands as a cornerstone in the mattress production industry, designed specifically to craft the iconic Bonnell springs—coiled, hourglass-shaped components renowned for their durability and support. This specialized equipment has revolutionized how manufacturers meet the global demand for comfortable, long-lasting mattresses, combining precision engineering with efficient production capabilities.

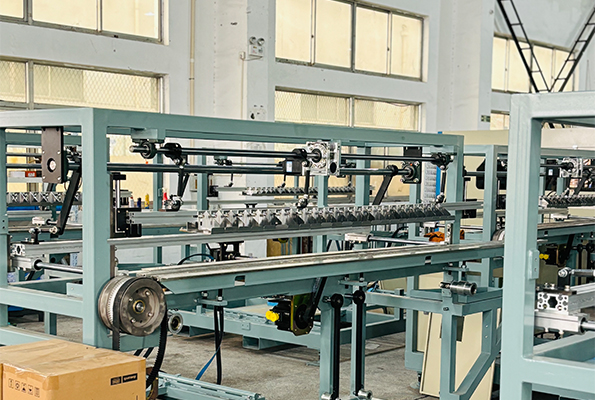

At its core, the Bonnell spring machine operates through a series of automated processes. It starts with feeding high-quality steel wire into the machine, which is then bent, coiled, and heat-treated to form the distinctive hourglass shape. Advanced models integrate computerized controls, allowing operators to adjust spring height, coil diameter, and wire gauge with exceptional accuracy, ensuring consistency across every unit. The heat-treatment step is crucial, enhancing the steel’s elasticity and resistance to wear, so the springs maintain their shape and support for years.

Widely adopted by mattress factories worldwide, this machine caters to both mass production and custom orders. Its ability to produce hundreds of springs per minute significantly boosts productivity, reducing labor costs and meeting tight delivery schedules. Beyond standard mattresses, Bonnell springs manufactured by these machines are also used in hotel bedding, hospital mattresses, and RV cushions, thanks to their reliable performance and cost-effectiveness.

In an era where consumer demand for quality sleep solutions grows, the Bonnell spring machine remains indispensable. It balances efficiency with craftsmanship, enabling manufacturers to deliver products that combine comfort, durability, and affordability. As technology advances, modern Bonnell spring machines continue to evolve, incorporating energy-saving features and smarter automation to stay at the forefront of the bedding industry’s needs.