In the rapidly evolving electric vehicle (EV) industry, battery performance is a key factor determining both driving range and safety. As a crucial component of the battery thermal management system, the battery pack cooling plate ensures stable battery operation by efficiently conducting and dissipating heat.

1. Materials and Design

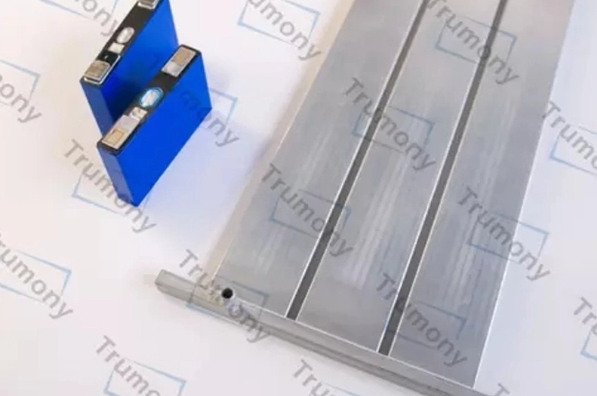

Battery pack cooling plates are typically made from aluminum, copper, or composite materials. They feature intricate internal flow channels that enable efficient coolant circulation.

2. Thermal Management Role

During battery charging and discharging, the cooling plate rapidly absorbs heat to prevent performance degradation, reduced lifespan, and potential safety risks. Liquid-cooled designs can maintain battery temperature fluctuations within ±2°C, supporting stable operation in environments from -30°C to 50°C.

3. Industry Application

Leading automakers such as Tesla use serpentine flow channel designs to enhance heat dissipation and extend battery life.

4. Technological Advancements

New composite cooling plates combine the thermal conductivity of metals with the lightweight benefits of polymers, reducing weight by up to 20% and improving heat dissipation by up to 30%. Micro-channel structures increase contact area with coolant, further enhancing cooling performance. Intelligent control systems dynamically adjust cooling intensity based on real-time battery status, balancing efficiency and performance.

5. Future Outlook

Cooling plates will move toward greater integration and intelligence. By becoming part of the battery structure, they will also contribute to structural support and electrical insulation, helping electric vehicles achieve higher safety and reliability standards.