Ensuring Battery Stability in Demanding Applications

As batteries power increasingly critical systems—from electric vehicles (EVs) to grid-scale energy storage systems (ESS)—thermal stability has become a top priority. Excess heat generated during high-current charging, discharging, or from dense cell configurations can shorten battery lifespan, lower energy density, and even lead to thermal runaway. Among various cooling methods, battery liquid cold plates have emerged as a highly efficient and reliable solution, effectively controlling heat to maximize battery performance and safety.

Working Principle: Efficient Heat Transfer through Direct Contact

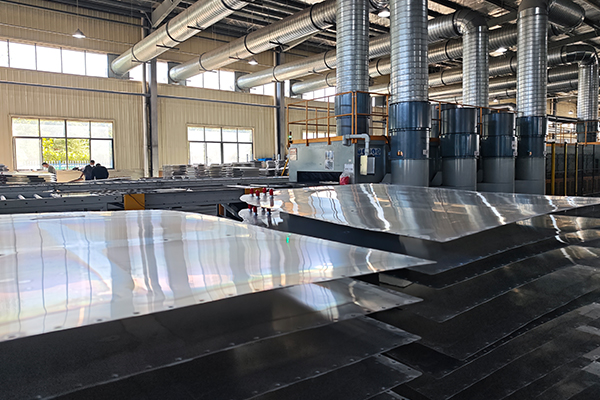

A battery liquid cold plate functions based on a simple yet effective mechanism: direct thermal contact with battery cells. Typically made from high-thermal-conductivity materials such as aluminum alloys or stainless steel, these plates contain internal microchannels that guide a circulating coolant—usually a mixture of ethylene glycol and water. As the coolant flows through the plate, it absorbs heat from the battery cells. The heated coolant is then cooled by a radiator or chiller, forming a closed-loop circulation system that maintains consistent operating temperatures.

Advantages over Air Cooling Systems

Compared with conventional air cooling, liquid cold plates offer distinct performance advantages:

Higher Heat Transfer Efficiency: Provides 5–10 times greater cooling capability, making it ideal for high-power applications such as EV fast charging.

Uniform Temperature Distribution: Maintains temperature variation within 3°C, preventing localized overheating and extending cell life.

Compact Structural Design: Saves space within densely packed battery modules, eliminating the need for bulky air-cooling components.

Optimized Design for Maximum Efficiency

To achieve optimal thermal management performance, careful design considerations are essential.

Material Selection: Aluminum offers excellent conductivity and lightweight properties, while stainless steel ensures corrosion resistance in harsh environments.

Channel Geometry: Variations such as serpentine, parallel, or microchannel designs influence coolant flow and temperature uniformity. Microchannel structures, in particular, enhance surface area and improve heat dissipation.

Sealing Integrity: Leak-proof sealing is crucial to prevent coolant leakage that could cause electrical short circuits or performance degradation.

Applications and Future Development

Battery liquid cold plates are widely applied in electric vehicle powertrains (e.g., Tesla, BYD), grid-scale energy storage systems, and high-performance portable electronics. As energy storage technologies advance—especially with the rise of solid-state batteries—liquid cold plates will continue to evolve. Future improvements will include smart temperature monitoring systems, integrated sensor feedback, and the use of environmentally friendly coolants to enhance system sustainability.

Conclusion

Battery liquid cold plates play an indispensable role in ensuring the reliability, efficiency, and safety of modern energy storage systems. As battery technology progresses toward higher energy density and faster charging, liquid cold plates will remain a cornerstone of advanced thermal management solutions.